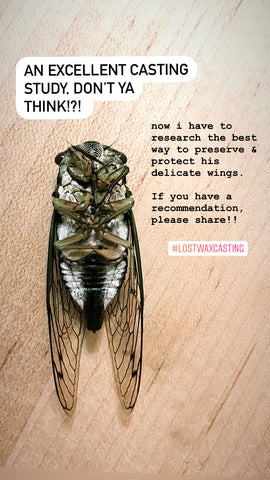

My little cicada project has been quite the popular subject this past week. I've been sharing the milestones with this little guy, as I make progress in the studio and inch closer to being able to incorporate into new jewelry designs.

A little context might help . . .

A few weeks ago, my husband brought home a "gift" of a perfect little cicada specimen. (*fyi - the poor little guy had already met his fate by the time my husband found him). Might sound odd to the lay-person, but since the 'songs of the cicada' started this summer, we've been chatting about how cool it would be to cast a cicada and perhaps work some of the elements into some nature-inspired jewelry designs.

So, you see why I call it a "gift"!?

I have never cast organics before, so after inquiring with a few jewelry / casting friends, I decided I'd make a mold (rather than direct cast) as I only had one specimen and casting is always an experiment . . . it might work, but it might not. So, rather than gambling with the only specimen I had, I decided to make a mold which would allow me to still have the original specimen in hand should something go wrong.

First the delicate wings were detached . . . Surprise!!, I found there were actually 2 pairs of wings - who knew? I then set out to do the preparations for mold-making by strengthening the wings with a bit of pink wax and the heat of my wax pen. *Thats what you see pictured; they look like little stained-glass windows, don't they?

I then moved on to setting each specimen onto little wax 'stilts' to prepare the mold frames, followed by mixing the 2-part silicone compound plus a few rounds of de-gassing on the investing table, and then an overnight rest to cure the compound.

On Thursday, I removed all of the cured molds from the frames, and now they sit on my wax bench waiting for me to carefully cut them open. This next part is tricky (& dangerous), so I gotta be up for it. It's a slow, focused sort of activity.

Although all this progress occurred over a number of days throughout the week, I made a quick video recap of the journey thus far. It's crazy how quick it looks, when in reality it's a pretty long and thorough process!

Once the molds are open, I'll test out the performance by injecting wax into each one. Fingers crossed, they perform and all the cool patterns translate to the soon-to-be wax pieces. Yeah, I'm pretty excited!

Provided all of that works . . . I can then sprue up the wax pieces and transform them into metal via the lost-wax casting method. And then, I should have some pretty cool pieces to work into jewelry designs!

If you have any questions, please ask me! I love sharing information about the process. Not a lot of people share this side of making. I personally love any behind the scenes views, and it helps convey the story of how jewelry is really made.

Until next time . . .

~ Barb

** If you aren't yet a member of my VIP / Friends List - sign up here - and you'll receive a discount code + updates when I release new designs or have events or specials.